When you’re planning a fabrication run for a new product, electronic component prices will become part of the calculation at some point. Some components are major cost drivers of new products, while in other cases component prices don’t really matter in the big picture. In some cases, defaulting to the cheapest components creates unacceptable risk for multiple reasons. So when should you choose electronic components based on price rather than some other criteria?

There is no single answer to this question. Most guides on supply chain management and component selection focus only on cost, but there are times where selecting a more expensive component is the best course of action. At some point, the cost of your components won’t matter so much as other factors become the major per-board cost drivers for your PCBA. To get started with costing out a board and looking for places to cut costs, it’s important to know the major cost drivers of a new board.

Major PCBA Cost Drivers After Parts Cost

The major PCBA cost drivers include the obvious points like fabrication and per-part costs, but there are other factors that can influence whether electronic component prices become the most important consideration. Per-part component costs are rather simple as they are fixed by the component manufacturer and distributor. The board fabrication/assembly costs and other factors unrelated to manufacturing can overwhelm per-part costs in certain situations.

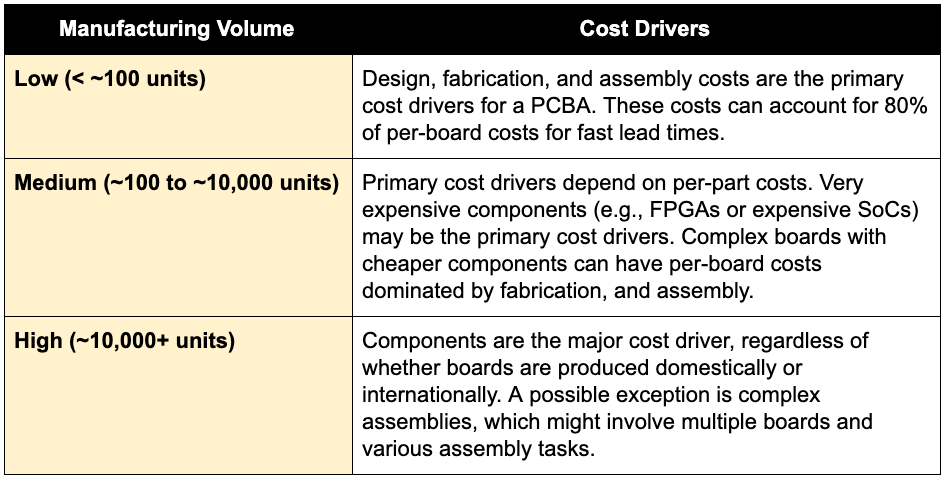

Manufacturing Volume

The price for fabrication and assembly depends on the volume you need to produce. Eventually, per-board fab/assembly costs will be much lower than per-board component costs. The table below shows roughly when the major cost drivers transition from per-board to per-part costs for different manufacturing volumes.

Lead Time

Another factor that influences manufacturing volume is lead time; if you need a 1-day turn, you’ll pay a lot more than you would pay for a 20-day turn. This is often overlooked by new designers, but it’s important to know that accepting a longer lead time will get you to a lower per-board price, especially when producing at low volume. At moderate to high volume, you’re back to a situation where components again dominate PCBA costs. Just like manufacturing volume, lead time becomes much less important at low volume.

Product Lifetime

Products like medical devices, military equipment, specialty test and measurement equipment, and replacements for legacy systems may require components with long lifetimes or obsolete components. At this point, you should worry more about longevity than price. An alternative strategy is to focus on components that have plenty of replacements as there is likely to be a compatible component available in the future. Larger manufacturers with extensive product lines will generally have plenty of compatible replacements available over a longer period.

Developer Support

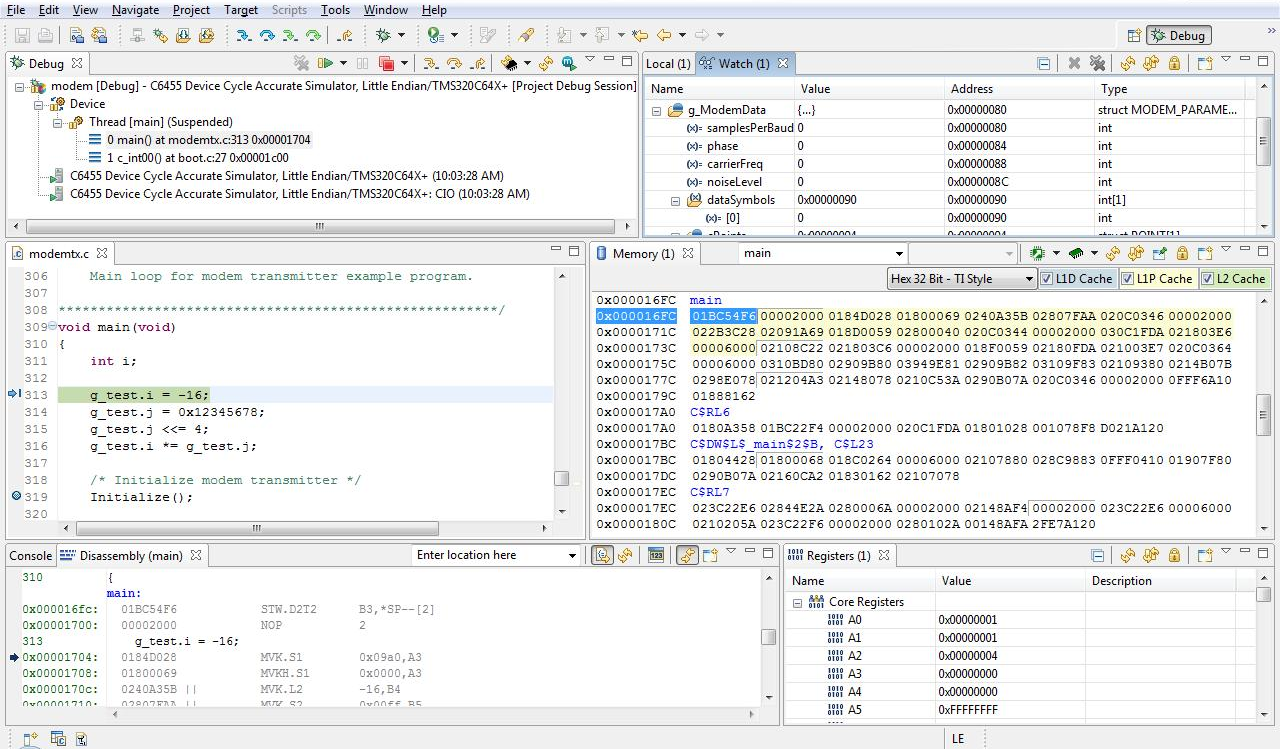

For components like MCUs, FPGAs, SoCs, or other PLDs, manufacturer support and community support are extremely important and should be considered alongside price. Major embedded processor manufacturers like Texas Instruments and Microchip have done considerable work to provide development and IDE support through example projects, developer tools, and code libraries. Components from these IC manufacturers also have robust support from the open source community. These components might be a bit more expensive, but this offsets your development time considerably and can lead to big savings on low to moderate volume PCBA runs.

Code Composer Studio and Uniflash are two utilities from Texas Instruments that help developers quickly create, compile, and flash code to their devices.

If a cheaper processor lacks any kind of concrete developer support from the manufacturer, your development costs go up considerably. Even worse, the end user may find that they are unable to debug or update their system after it’s deployed, forcing a redesign with a newer component. This reduces the lifetime of the final product and forces the end user to default to the more expensive component during a redesign. Addressing this early reduces the risk of obsolescence and redesigns after the product is finished.

Look at Electronic Component Prices Early

No matter your manufacturing volume or fabrication costs, you should still examine component prices early in the design process. Given two components that have the same functional capabilities, part lifecycle status and projected lifetime, and manufacturer support, it’s appropriate to use the lower cost component as long as it can be procured at the required volume. Because the factors driving PCBA cost span beyond just per-part costs, it’s important to look at component prices early with the right supply chain tools.

When you need to find electronic component prices and compare technical specs for components, use the advanced search and filtration features in Octopart to find the parts you need. The electronics search engine features in Octopart give you access to updated distributor pricing data, parts inventory, parts specifications, and CAD data, and it’s all freely accessible in a user-friendly interface. Take a look at our integrated circuits page to find the components you need.

Stay up-to-date with our latest articles by signing up for our newsletter.