If you’ve worked with sensors that have very low voltage outputs, such as load cells or other Wheatstone bridges or current transformers, you’ll know that you need a very precise amplifier and a high bit-count analog to digital converter (ADC) to utilize their measurements. Most of my circuit boards tend to have very tight size constraints, so integrating more components isn’t always an ideal solution. However, by using a high bit-count ADC with a programmable gain amplifier (PGA), you can save significant board space and also improve consistency of readings across a batch of boards.

A strain gauge in a load cell might have a full range output of just 1mV per volt, which if run at 5 volts will give you a signal of 0-5mV for the full sensor range. This makes a 100kg load cell give a signal of 50μV per kilogram, which would provide no usable data without significant amplification. Even with 128x amplification, the signal at full load would be just 0.64 volts, which would give you about a far from ideal 2kg resolution with a 3.3 volt 8-bit ADC. Most modern ARM controllers have a 10 or 12-bit ADC however, which would give you a resolution on the loadcell of about 125 grams. This is still rather poor, so we can look at external ADCs which offer much higher bit-count to be able to get a satisfactory resolution. Utilizing a 24-bit ADC with a 128 V/V amplifier, our 100kg load cell can now read milligrams. This high resolution allows precise measurements and becomes critical for precision industrial applications that might be using load cells with a full-scale range of multiple tons (eg: cranes, weighbridges) or current sensors that have to deal with potentially thousands of amps (eg: office buildings, factories). The extra resolution also allows for filtering the signal to ensure a stable reading and a high degree of confidence in the reading.

Programmable Gain Amplifier

Programmable gain amplifier ADCs are a bit more expensive than a regular ADC of the same resolution but have proved to be well worth the extra expense in my projects. Not to mention, a solution using an ADC with a precision op-amp and precision capacitors and resistors will often equal the cost of the integrated unit, and therefore offers no real advantage. The integrated PGA solution also offers significantly reduced board space, as well as much more consistent signal amplification from board to board. With the gain being easily programmable, it also makes switching to different sensor options very easy, giving you full resolution support for a range of sensors.

If you’re using your microcontroller’s ADC or another external ADC that lacks the integrated programmable gain amplifier, standalone PGAs are also readily available on the market. Texas Instruments’ PGA281 is a very popular choice with up to 128 V/V amplification of differential or single-ended signals.

Analog to Digital Converter

From the example above, you can see that the 12-bit ADC in a good microcontroller doesn’t really cut it for small signal voltages. If you’re using something like the ATmega that is popular in Arduinos, you only have an 8-bit ADC, which is far more limiting still. An external ADC is therefore required to be able to read such small voltages with enough precision to provide usable data.

Whilst high bit-count is important, it’s not the only factor that is important. When dealing with small voltages, your ADC needs to be low-drift, have a very stable reference voltage, and have sufficient bandwidth to capture your signal. A high bit-count on an unstable or drifting ADC will still give you inaccurate readings.

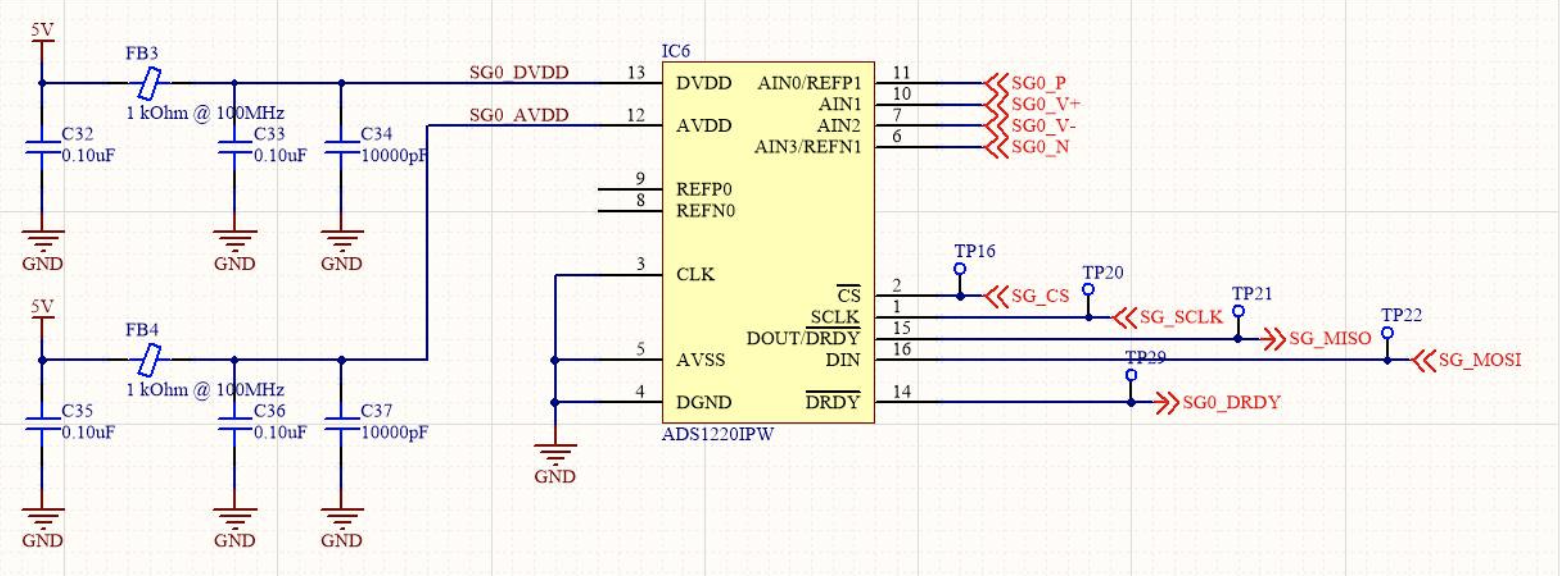

I tend to turn to the Texas Instruments ADS1220 for reading current transformers or strain gauges because it is very stable and fantastically precise. It’s a 24-bit ADC, but with the internal filter, it gives you an effective 20 bits of usable resolution. That being said, this is how I connected my ADS1220 in one of my projects:

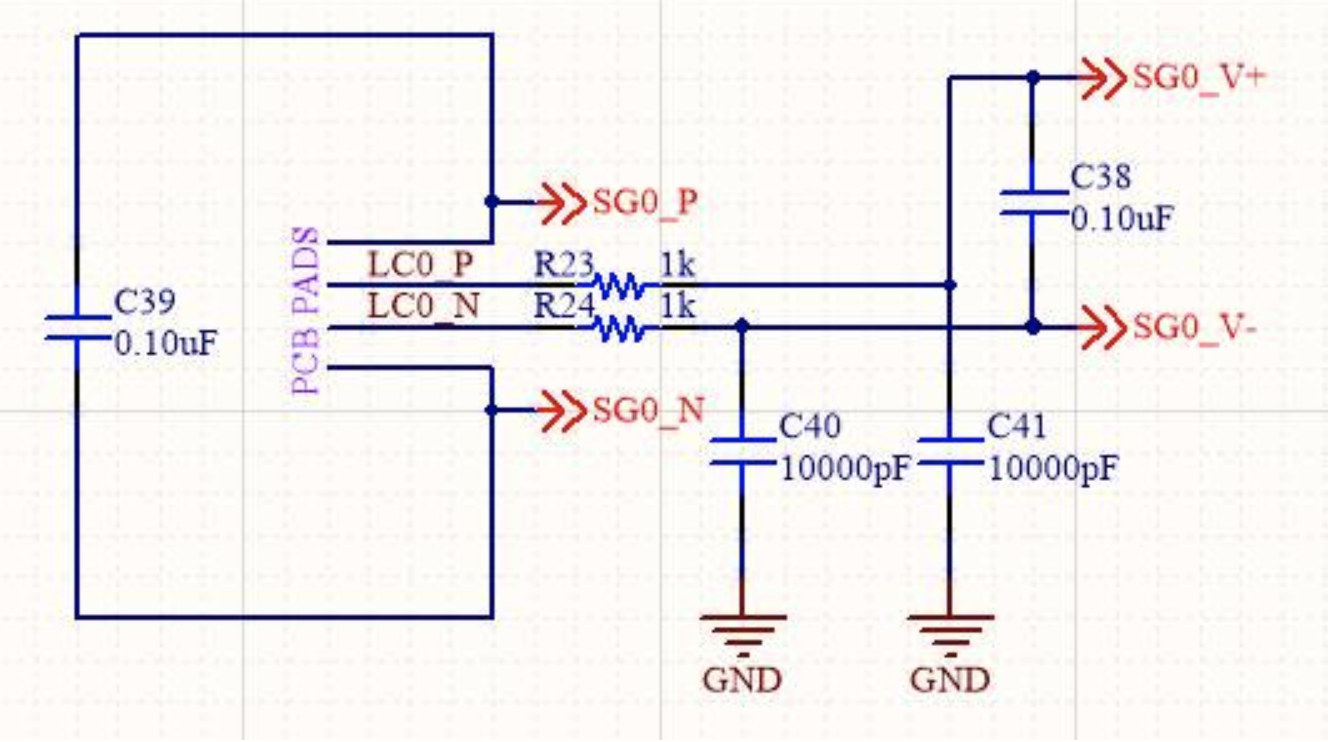

The implementation of the circuit is fairly critical. I have a pi filter that uses a ferrite bead rather than an inductor on the inputs, with some very basic filtering on the inputs of the load cell as can be seen here:

This circuit was used for measuring data for a Canadian Olympics team using an Omega LCM302 2000 Newton load cell. When comparing the recorded data to the same impulses recorded on top-of-the-line athletics force plates, the ADS1220 data was able to read short duration impulses far more precisely, as it was taking readings at 960 samples per second, and the results had less signal jitter and drift as the temperature changed.

The programmable gain amplifier and having the load cell be powered from the ADC directly made swapping to a load cell with a smaller full-scale range easy by just changing the amplification through configuration or when an overload was detected. This makes the 4 input ADS1220 much more attractive for my applications than its slightly cheaper single-channel sibling, the ADS1246.

There are plenty of other options on the market, however, and some of them may be better suited to your specific application, so why not explore some of the options on Octopart by looking through the ADC category and searching for ‘PGA’.

We hope you found this article useful! If you'd like to have content like this delivered to your inbox, sign up for our monthly newsletter!